Physics Meets AI for the CO2-reduced Manufacturing of Steel Products

The manufacturing of high-quality steel products with customized properties and a reduced CO2 footprint is possible through the use of physically informed artificial intelligence.

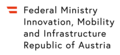

Deep Learning for Refractory Materials

A deep learning-based approach enabling the automated evaluation of the particle dissolution rate with high precision.

Predictive Modeling of Strength in High Entropy Alloys

Computational design of alloys can reduce cost of advanced materials development

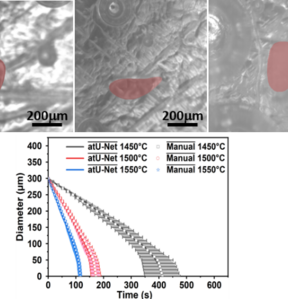

Tool Condition Monitoring for Drilling Tools for Better Productivity and Process Reliability

Real-time diagnosis of damage via sensor data analyses during on-going production operations enables major increase in efficiency.

Prediction of Decisive Material Properties of Aircraft Components

MCL is developing a model network that predicts spatially resolved fracture toughness and strength in the aircraft component.

Use of Probabilistic Programming Languages for Material Models

Researchers at MCL and TU Wien use new programming languages to make material models more meaningful.

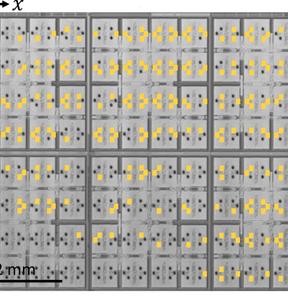

Towards the Zero-defect Management of Through Silicon Vias (TSVs) in the Production Line

Advanced defect localization and classification of TSVs at Wafer Level Using Machine Learning Methods.