The coupling of simulation and experiment is the basis for the development of reliability tests at the MCL. Especially for components with a very long lifetime the prediction is very complicated, time consuming and expensive.

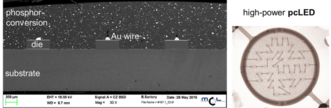

High power light emitting diode (LED) has gained more and more importance over the last decade as a long-life general illumination source. To ensure a long-lasting lifetime of the LED module, knowledge about critical failure modes has to be generated. However, it is extremely time consuming and complicated to assess the failure mechanisms and the reliability of the whole LED system.

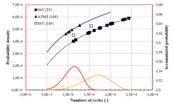

At the MCL, a universal method for the design of tests was established and successfully exemplified on LED modules. We investigated an accelerated test method based on a dynamic mechanical analyser (DMA) to transfer the time-consuming electrical switching test (SST) into a fast, purely thermo-mechanical one (ATMT). The electrically induced thermo-mechanical stress levels due to switching cycles are modeled with experimentally validated finite element multiphysics simulations to compare thermally induced strains and stresses with equivalent, purely mechanical stresses causing similar strain/stress scenarios.

This result of the simulation was transferred into an experimental setup that consisted of a DMA. There, deformation was applied by a compression tool mimicking the thermal expansion of the silicone and consequently leading to similar failures as observed in the SST test.

The occurred failure modes and the comparable number of cycles until failure represent the possibility to replace the SST with the ATMT in the future. These findings can be considered as a further step for the development of an alternative accelerated testing procedure based on thermo-mechanical fatigue for replacement of traditional standards.

Contact: Elke Kraker