Due to the thermal inertia of the core regions, management of heat treatment process control related residual stresses is particularly important for large component dimensions. The excess of critical stress levels during oil and water hardening of steels, caused by high temperature gradients, frequently leads to hardening cracks and as a consequence usually to rejection of the whole heat treated batch.

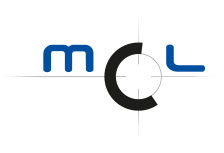

Current research work aims at prevention of the appearance of hardening cracks during quenching of massive die casting moulds and thereby the prolongation of their life time. To this end, multi-phase simulation techniques and models are developed for the prediction of the residual stress development inside the components. The models take the phase transformations upon quenching and the thereby associated transformation induced plasticity (TRIP) into account.

In the same way, MCL performs instrumented heat treatment experiments with correspondingly shaped large specimens to recreate the complex loading situation that occurs during hardening of the moulds. By coupling the results with finite element simulations, critical regions in the component geometry can be identified and the process control during hardening can be customised to achieve a favourable residual stress state.

![[Translate to Englisch:] Wärmebehandlung große Druckgußform](/fileadmin/_processed_/c/6/csm_WBH_grosse_Werkzeuge_Bild_2_3a800e4320.jpg)

![[Translate to Englisch:] Berechnete Spannungsverteilung in einem Bauteil beim Abschrecken (Härten)](/fileadmin/_processed_/5/9/csm_Spannungsoptimierung_Bild_2_4663387609.jpg)