Improved performance and longer lifetimes of metalworking tools are a much-needed core competence for sustainability-oriented production. To improve this performance, the Materials Center Leoben Forschung GmbH (MCL) works in cooperation with companies that manufacture drilling and milling tools as well as the steels and hard coatings used for them. Wear-resistant coatings with good adhesion play a central role in the service life of tools. To improve the adhesion of the coatings, the tool surfaces are subjected to an ion etching process before coating. In addition to changes in the surface topography, the metal ion etching process also causes chemical changes on the steel surface because the used metal ions can accumulate on the surface of the steel.

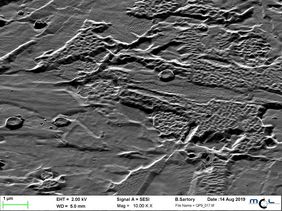

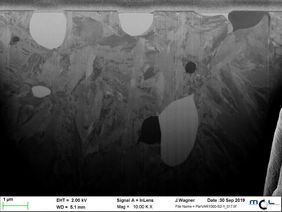

Within the research project, the effects of different metal ions such as chromium and titanium on surface topography changes during the metal ion etching process were investigated. It was found that different ions create different structures on the steel surface. The etching process creates features, which allow the coating to mechanically interlock with the steel substrate or provide favorable attachment positions for the coating atoms during the coating process. By selective etching of certain carbides by titanium ions it is possible to create pits whose edges improve the mechanical interlocking between substrate and coating. In contrast, for chromium ion etching it is observed that the etching behavior depends on the orientation of the individual martensite blocks and thus again offers favorable adsorption sites for the atoms of the coating material.

How emphasized the surface features that arise during etching can be controlled by various parameters, such as the number of axes around which the tool rotates in the coating chamber, or the level of electrical voltage applied during the coating process. These parameters influence material removal rates and implantation depths of the ions.

Another parameter that has a great impact is the roughness of the workpiece, which influences the martensite block sizes and stresses in the nearby surface area. The investigation of the roughness influence is of industrial value, since many workpieces are not polished for reasons of cost and time, but have a certain roughness. Here it has been shown that a rougher surface can have a positive effect for some applications, as it leads to uniform material removal and a homogeneous surface structure.

Impact and effects

The investigation of the metal ion etching process within the project P2.7 "ISuCoSy" leads to a better understanding of industrial metal ion etching processes. By understanding the above-mentioned parameters, surfaces can be adjusted to guarantee an improved interface between substrate and coating for different requirements.

Project coordination (Story)

DI Juliane Kampichler

Junior Scientist Hard Metals

Department Materials

T +43 (0) 3842 45922-0

juliane.kampichler(at)mcl.at

Projektpartner

Gühring KG, Germany

voestalpine Böhler Edelstahl GmbH & Co KG, Austria

voestalpine eifeler-Vacotec GmbH, Gemany

LMT Fette Werkzeugtechnik GmbH & Co.KG, Germany